Chemical contamination awareness, spill containment, and subsequent regulations has had huge advancements in the 21st century. It might surprise you then to know how many companies are still letting things go down the drain. A leak here and there, a few drops of oil washed into the gutter… It can’t have that much of an affect. Right?

WRONG! According to Kim Ward, Zero Waste Outreach Specialist, just a single drop of oil can contaminate 1 million drops of clean water. This means that with the global demand for crude oil approaching 100 million barrels per day (Statista, 2017) the risk of contamination of the earth’s water supply is more than a reality.

It is a potentially cataclysmic event.

Let’s assume you’re an environmentally conscious individual and you certainly aren’t part of these statistics. And maybe neither is the corporation that you work for. You are ready for the smaller events that are seemingly inevitable. Or are you?

At Industrial Fluid Solutions (IFS) we believe that every facility that deals with or handles fuel, chemicals or lubricants should be prepared and equipped with basic spill kits and decontamination procedures.

What does our country’s regulations say?

The South African National Standards (SANS) 1186 stipulates “all transporters, manufacturers, suppliers and industries working with a Hazmat Product is to ensure that every proactive measure is taken to ensure firstly the prevention, active management and in the event of a spillage, the re-active and proper management of spillages. “

Obviously, these regulations exist for a reason. One way to pro-actively raise awareness around the plant is to install safety and preventative signs. I’m sure you already did that. But another, less obvious, way to improve focus on environmental awareness and worker safety is to install spill kits in strategic positions. Yes, a visible spill kit serves as a visual reminder that things can go awry. For this reason the answer to the question “why do I need a spill kit?” becomes more and more obvious.

Industrial spills are avoidable! You can prevent contamination with the proper measures in place. But according to an article by Karen D. Hamel of ESH Today, if it does happen, this is what you need to do:

- Assess all possible risks – Assess all aspects of the spill which may pose a threat to human health, the environment and property response to identify all possible risks.

- Appropriate PPE – Choose the correct Personal Protective Equipment (PPE) for the situation. These PPE items used should be in accordance to the respective rules and regulation.

- Confining the spill – The aim in mind here is to block, divert or confine the spill as QUICKLY as possible. This is to stop any further contamination, especially water contamination. This is arguably where a simple spill kit is most effective, giving a quick and effective response.

- Stop the source – One of the first priorities should be to confine the spill. But straight after, implementation to stop the source of the spill should commence. For simple spills, this may just involve turning a drum upright. But at times it can also involve plugging or patching a leak.

- Spill clean-up – Once you’ve contained the spill and stopped the source, it’s time for cleaning up the remainder of the spill. This may include any decontamination if need be. Dispose of all saturated absorbents in the correct manner.

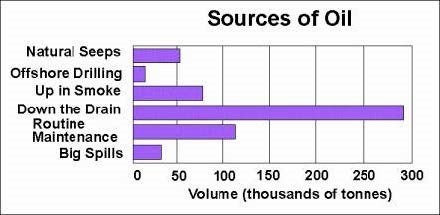

What exactly are the stats?

Yes, a lot of pollution in this regard is created by big spills from large tankers who fall victim to accidents, mechanical failure, or even fluid theft, but believe it or not, a high majority is actually as a result of handling issues, accidents, and inevitable circumstances on a smaller scale or site-specific environment.

On the surface it would seem like for the most part the big guys like mine sites, workshops and industrial installations do their utmost to prevent spills and chemical contamination. But despite having preventative measures in place and subscribing the best practice protocols, they are the guys handling the most volumes of hydrocarbon contaminants. Offshore drilling obviously also come under the spotlight, but this industry seems to be well governed and face huge fines if they disregard the international guidelines, so that leave guys like you and I. Unfortunately, that’s the stats, the medium enterprise and second tier consumer is the weakest link in the chain where most of the unaccounted-for disregard for our natural resources take place.

What can we do to keep our water clean?

Seeing as how little oil is needed to contaminate vast volumes of water, the first port off call should naturally be the oceans and waterways when it comes to cleaning up the oily waste us humans spread.

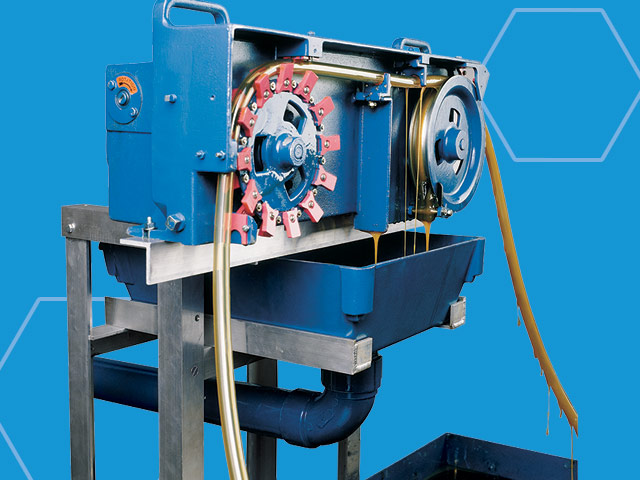

Floating contaminant booms and oil skimmers can take care of this type of situation. Often deployed on a huge scale when ocean spills occur, this solution is seen as the most efficient floating pollution-control measures for open water. When it comes to basic decontamination of industrial water, an oil separator will do the trick and is often deployed as part of a staged cleansing and filtration process.

Let’s break it down, what do these kits consist of?

Choose your spill kit according to the type of plant, site or workshop operation and or the potentially hazardous fluids you are using.

Visit the Fluidtrans Online Store. Or take a look at the Contamination Control Product Catalogue to see the full range of products.

Absorbents

- Absorption socks – One places absorbent socks on the perimeter of a spill to stop it from spreading further.

- Absorption pillows – The pillows have a large surface area. This allows them to absorb high quantities of liquid over a short period of time.

- Coco peat absorbent – Coco peat is a natural, renewable and bio-degradable substance with fast absorption properties. A 22kg pack is able to absorb around 220L of oil, fuel and petroleum-based products.

- Chemical absorbent scatter – Similar concept to coco peat, but more ideally suited to chemical and acid spillages. 500g absorbs around 3L of liquid.

Spill control and clean up

- Polyethylene Shovel – This shovel is durable and manufactured from polyethylene to create an anti-static and non-conductive product.

- Dust pan and brush – Non-spark product which is acid resistant and included with all truck and tanker spill kits.

- Industrial Broom – Hard wearing industrial synthetic broom to assist with quick and easy spill clean-up.

- Heavy duty recovery bags – These bags are high quality and durable and made from polyethylene. These bags are for industry specific needs.

- Plastic wheelie bin – These wheelie bins come in various sizes. It’s also available in spill kits for all specialty spill kits and universal kits.

- Durable Bucket – The bucket serves as a more compact alternative to the wheelie bin. You can easily store these in smaller spaces. Also ideal for spills of a smaller size.

- Personal Protective Equipment (PPE). Included in the spills kit are dust masks, safety goggles and heavy-duty PVC gloves. This ensures the greatest possible worker safety when dealing with spills.

There are various spill kits available for spills of different liquids. Each is tailormade to cater to workspaces and spills of various sizes. This ranges from kits that can absorb as little as 25L to as much as 10 000L. Spill kits are available for oils, fuels, coolants, chemicals and solvents. For those who work with non-aggressive oils and chemicals, a universal spill kit might me a better option.

Spill response is no new phenomenon. But we call for more than that. We call for a global move toward higher environmental consciousness and more pronounced appreciation for natural resources.

Now’s your time… Join the movement.